Types of gears

SPUR GEARS

Features:

1.Spur gears are a sort of tube shaped stuff.

2.There are no axial force in spur gears

Advantages:

1. It is easy to manufacture

Applications:

1.Transmission components

Disadvanatges:

1. they will produce vibration;

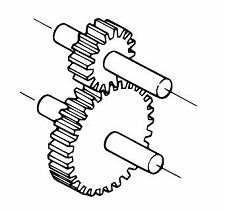

BEVEL GEARS

Features

1.Provides reduction ratios up to approx. 1:5

2.Has better proficiency of transmission with diminished gear noise

Advantages:

It have a advantage of increasing the speed of rotation of the chuck and this makes it possible to drill a range of materials.

Applications:

1. It consists machine tools, printing presses,Automobiles, tractors, vehicles and so on.

Disadvantages:

1.Involves some technical difficulties in manufacturing

HELICAL GEARS

Features:

1.Gears in cross section produce push powers in the axial direction.

2.Has higher strength compared with a spur gear

Advantages:

1.More effective in reducing noise and vibration when compared with a spur gear.

Applications:

1.It consists of transmission components, automobile, speed reducers, etc.

Disadvantages:

The helical gear efficiency is lower due to the contact between its teeth, which produces axial thrust and generates heat.

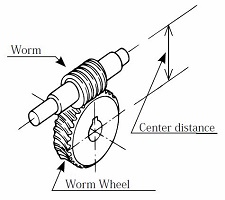

WORM GEARS

Features:

1. It looks like a standard spur gear with slightly angled and curved teeth.

2.It changes the rotational movement by 90 degrees.

Advantages:

1. It have a very quiet and smooth meshing action

Applications:

1. It includes speed reducers, antireversing gear devices making the most of its self-locking features, machine tools, indexing devices, chain blocks, portable generators, etc.

Disadvantages:

1.It is not possible for a worm wheel to drive a worm unless certain conditions are met