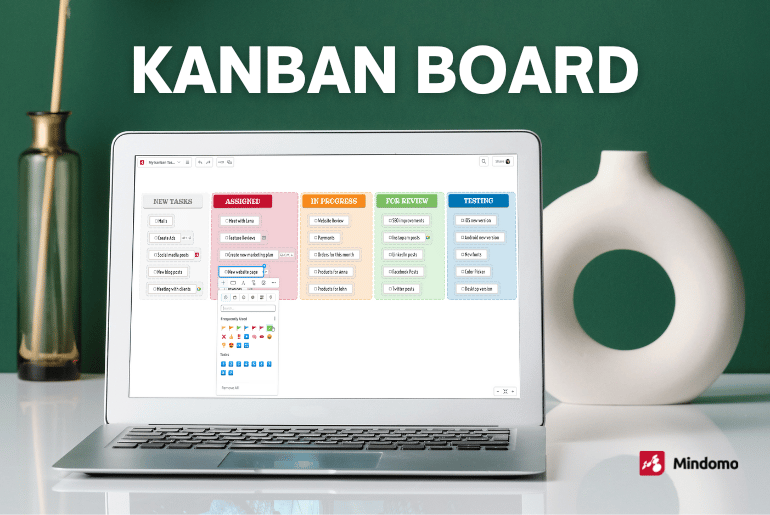

When projects get complex and have many moving parts, it’s important to have the right type of project management tool. One of the best methods to use, especially in technical development, is the Kanban method being used on a Kanban board. Its original roots come from lean manufacturing with a mindset of continuous improvement.

It has since been adapted as a part of agile methodology to handle time management better. It’s a type of graphic organizer that helps to show work-in-progress (WIP) limits. With software, it is an excellent alternative to a digital mind map that is also actionable as a time management mind map.

What does a Kanban board do?

When using the Kanban method, it requires you to build a Kanban board. This is where team members will place “sticky notes” for their work items. It’s an alternative to a digital mind map that contains a task list. It doesn’t just have to act as a business mind map but can also be used as a personal Kanban. A personal Kanban is about the individual to-do’s tracked daily.

For a business, it helps show the iterative steps to complete daily or weekly. When all tasks are done, the project is completed, and the Kanban board can be used for a new project. In addition, this graphic organizer shows where resources may need to be reallocated and where there is success.

What are the six rules for a Kanban board?

There are a set of rules to follow the Kanban method in business outlined below. The elements of a Kanban board should reflect them.

1. Never Pass Defective Products

This means don’t push products that aren’t fully ready. You should send only quality products to clients. Workflow should halt production or development until the defects are handled. Otherwise, you’re sending a physical product that may need to be recalled or a digital one that needs constant fixing.

2. Take only what’s needed

This is an efficiency system to ensure there’s no overproduction and thus less operational expenditure. Follow the backlog priority built and move the sticky notes that represent the necessary Kanban cards. Beyond the backlog, only focus and address customer features as any additional work items.

3. Produce the exact quantity needed

This is an efficient method again. It comes from the traditional manufacturing roots of the Kanban method. It’s not about producing as many Kanban cards as possible and then executing them. It’s about producing exactly what is needed for a successful product.

Whether that product is a minimum viable product or whether you’re manufacturing products, it stays the same. When you overproduce, you’re just wasting resources, be it time or money. You also end up producing something that may not be necessary or useable.

4. Level the production

This is about capacity measurement. That means you want your resources working at similar capacities appropriate to their level. It’s meant to ensure there are no bottlenecks in development due to dependencies not being met. Handling this properly will give ample time to reallocate resources if a bottleneck arises.

5. Fine-tune the production or process optimization

Here you want to consider diagram software or using digital Kanban boards. This will help to visualize the work that needs to be done and the flow of work as well.

Remember, Kanban is all about continuous work improvement. You want to improve your lead time, hit your due date, and limit work-in-progress items. You want to be able to track these metrics and continuously look for delays or flaws. You’ll naturally limit work-in-progress items and improve efficiencies by reducing defects.

6. Stabilize and rationalize the process

When you handle the actions above, you’ll hit a level of stability which is the final step. Document the process and turn it into a standard operating procedure to be shared with everyone. This can be done as a separate business mind map that’s easy to collaborate with the right diagram software.

What is the difference between Scrum and Kanban boards?

A Kanban board is used for the entire project cycle. That means it’s more of a project management tool that works to visualize tasks. A Scrum board, in general, is focused on the sprint. A scrum board is completely cleared with each sprint, and the next sprint starts fresh. A Kanban board only grows and shifts until project completion.

A kanban board is used all the way through the lifecycle of a project, whereas a scrum board is cleared and recycled after each sprint.

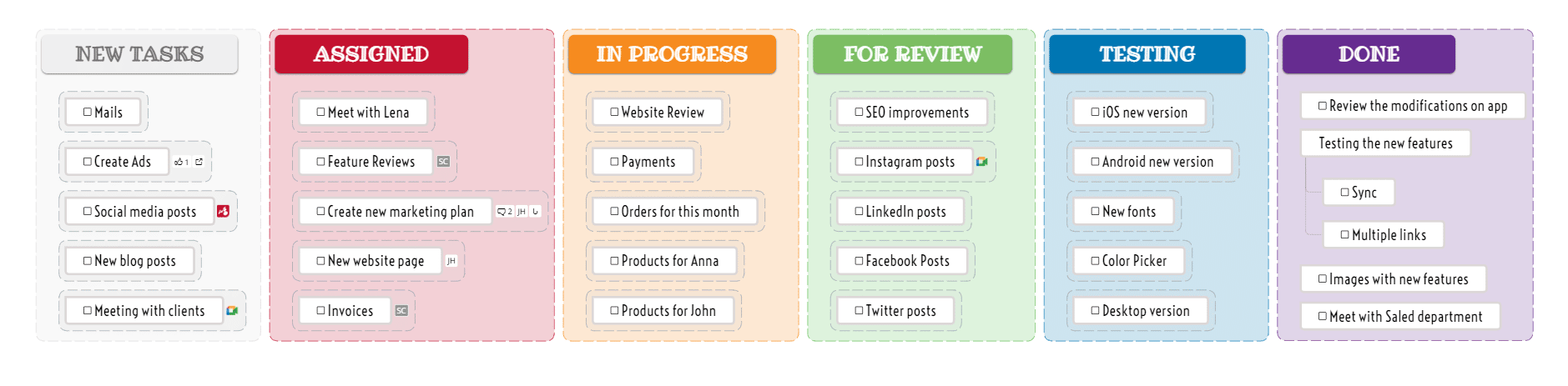

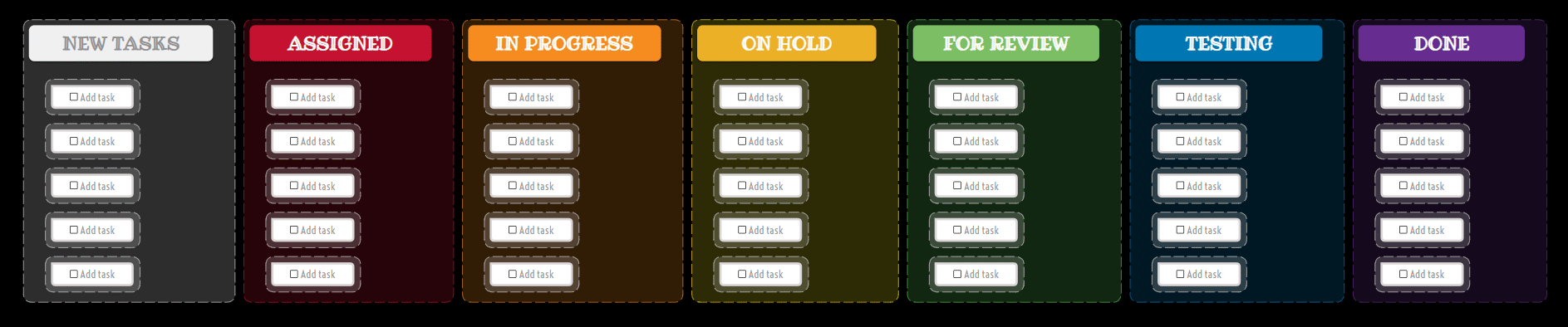

What columns should a Kanban Board have?

Part of the power of Kanban is its simplicity and also versatility in being able to add as many columns as necessary for a specific project. Each person can add/delete/rename columns as preferred, such as “to do”, “doing” and “done”. That means work items can get tasked appropriately, and the sticky notes show the amount of work being done. In addition, moving the sticky notes from one column to the next brings a sense of accomplishment.

There isn’t a due date per se, as it’s more about the flow of work and completing the board work. It should be a fluid daily check-in to ensure that progress is moving. When new items show up on the to-do list with new Kanban cards, they eventually move their way to done. It’s meant to act as a time management mind map, yet instead of tracking time, it’s tracking progress.

Go digital with Kanban

Digital Kanban boards are always great because you won’t have to keep replacing sticky notes. It’s easier to collaborate, and you won’t need to physically move the board of work from place to place. Sharing with team members is also simple. You can also easily sum up the number of tasks and incorporate other elements of a Kanban board.

Mindomo helps to make that a reality by helping you build out Kanban boards as well as a business mind map. Don’t let yourself reach your work-in-progress (WIP) limits by using this excellent time management tool and system. Take a look at our actionable Kanban templates and create your own kanban:

Keep it smart, simple, and creative!

The Mindomo Team